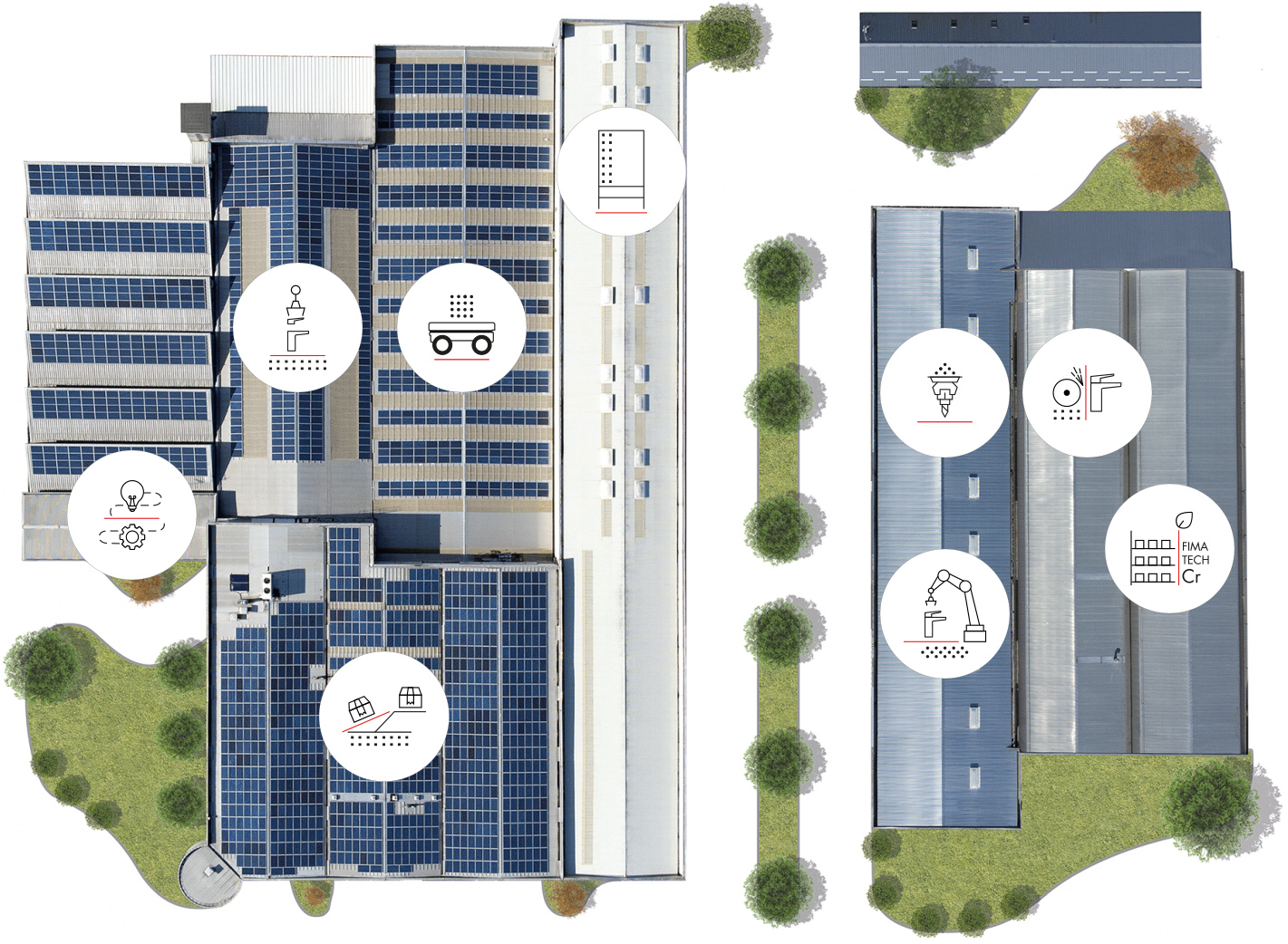

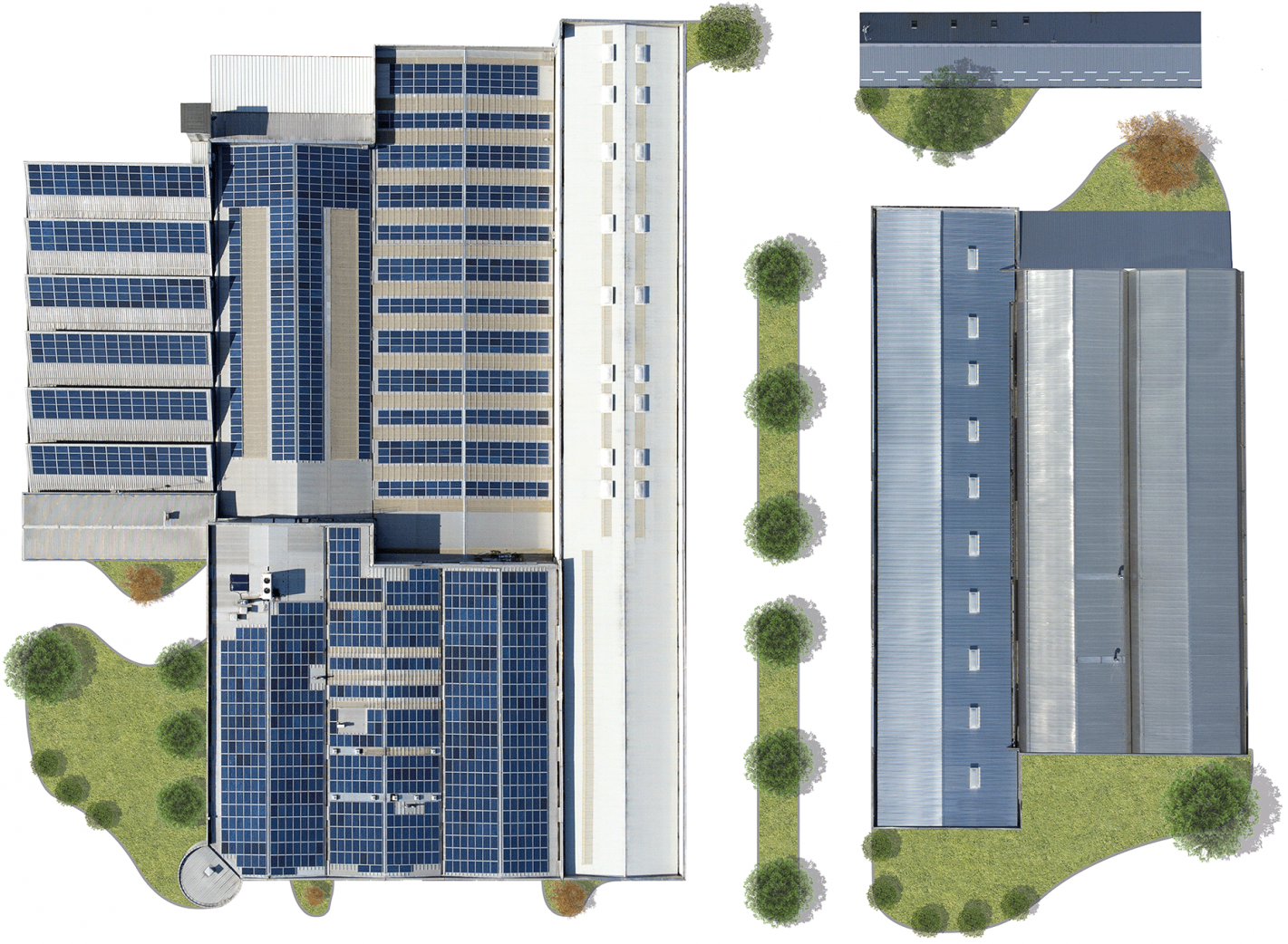

VERTICAL WAREHOUSE

AVG

...

![]()

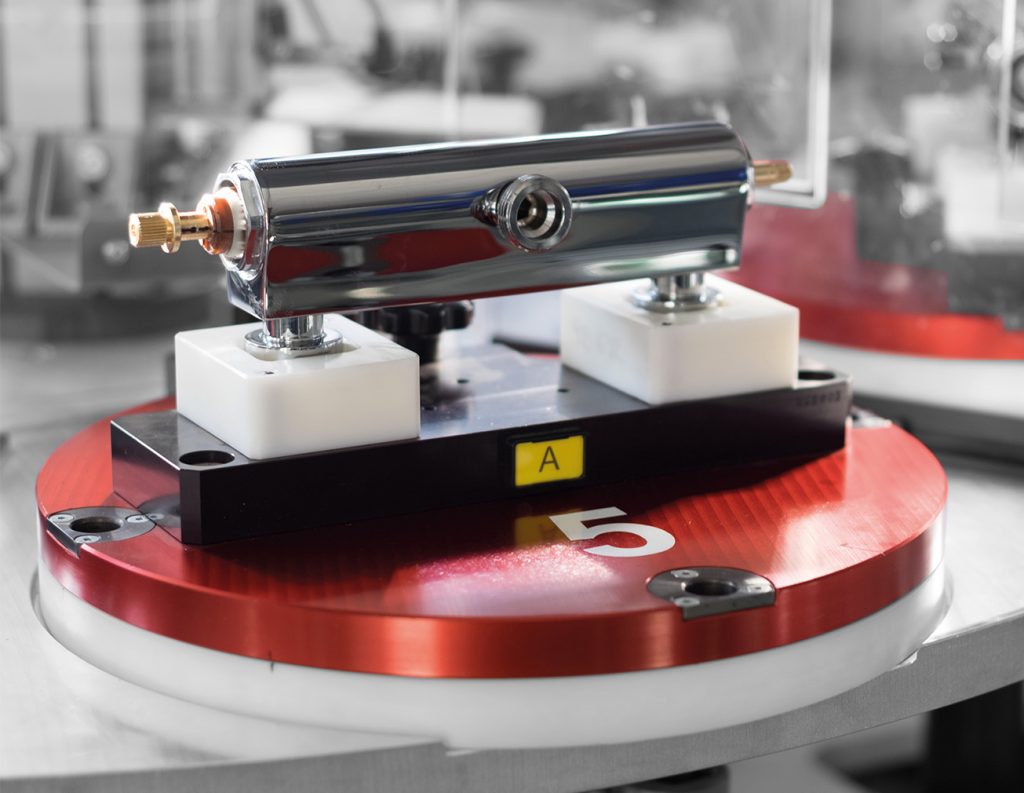

ASSEMBLY

Automatic installation

The assembly department is divided into

12 different assembling centers.

The 6 automated centres are dedicated to

the production of large lots.

Here each product is assembled and tested

one by one with a pressurized air system

that allows to detect even the smallest

imperfections and micro losses that could

evolve into defects in the product

during normal use.

Each assembling centre has its own warehouse

that makes it totally self-sufficient

and is daily supplied on the basis of the

orders and according to a logic aimed to

optimize the material handling.

FIMA RESEARCH CENTRE

Study and engineering

The Research and Development Centre

of the company is the place where the ideas

from the designers or from the sale demands

and the market come alive.

A team of experienced designers develops

day-to-day solutions with state-of-the-art equipment.

Each product processed before being put

into production is realized in

3D mechanical prototyping,

tested on water on special simulation

benches to understand the criticality

of its operation and then reworked.

Only once passed severe #quality tests,

the product is engineered, put into

production and distributed through

FIMA Carlo Frattini dealers.

SORTER

TURNING

Brass rod with numerical-control lathe

The CNC department is equipped with 8 CNC multi axis lathes

able to machine different sections of brass bars in an extremely

precise way and with high efficiency. All brass shavings are

collected also in this department with the innovative vacuum

system and are divided automatically on the basis of the

typology of brass. In this department we produce all brass

components that are part of FIMA Carlo Frattini products in

order to guarantee a complete control of the production and a

total reduction of the wastes by reusing the 100 % of the

production scraps.

TURNING

Moulded and casted items

In the machinery department all casted and forged bodies

are machined, drilled and threaded.

All the passages of the production are automated with optical

recognition robots and continuously controlled by the

integrated informatics systems. Any residue from the

processing is collected with a phased vacuum system that

immediately collects all the shavings of brass with a reduced

consumption of energy. After several washing treatments, the

shavings are collected in dedicated silos and are ready for being

transformed again in new brass bricks or bars in full respect of

the environment according to the #green philosophy of the company.

POLISHING

Metal polishing systems

In the polishing department, automatic machineries grind,

buss and polish every single piece in order to get the best

brilliant and shiny surface.

An efficient integrated aspiration system provides a clean

environment without durst and the collection of all brass

powders ensures a total recycle of materials with no wastes.

All products with a particular #design are entrusted and one by

one manually processed by expert operators in order to

guarantee an incomparable quality, brilliance and details.

ELECTROPLATING

Automated galvanic system

The galvanic department is equipped

with an automated galvanic system composed

by 44 different baths and able to produce all

the unique chrome, black chrome, nickel and gold

finishes of FIMA Carlo Frattini.

The system, realized with the

most innovative technologies, is totally #green

thanks both to the use of trivalent chromium,

completely safe for the health and the environment,

and to the scrupulous ecological plans and

closed cycle treatments able to clean all

discharged water with some cleaning resin systems.

FIMA RESEARCH CENTRE

Study and engineering

ASSEMBLY

Automatic installation

AVG

…

ELECTROPLATING

Automated galvanic system

The galvanic department is equipped with an automated galvanic system composed by 44 different baths and able to produce all the unique chrome, black chrome, nickel and gold finishes of FIMA Carlo Frattini. The system, realized with the most innovative technologies, is totally #green thanks both to the use of trivalent chromium, completely safe for the health and the environment, and to the scrupulous ecological plans and closed cycle treatments able to clean all discharged water with some cleaning resin systems.

POLISHING

Metal polishing systems

In the polishing department, automatic machineries grind, buss and polish every single piece in order to get the best brilliant and shiny surface.

An efficient integrated aspiration system provides a clean environment without durst and the collection of all brass powders ensures a total recycle of materials with no wastes.

All products with a particular #design are entrusted and one by one manually processed by expert operators in order to guarantee an incomparable quality, brilliance and details.

TURINING

Moulded and casted items

In the machinery department all casted and forged bodies are machined, drilled and threaded. All the passages of the production are automated with optical recognition robots and continuously controlled by the integrated informatics systems. Any residue from the processing is collected with a phased vacuum system that immediately collects all the shavings of brass with a reduced consumption of energy. After several washing treatments, the shavings are collected in dedicated silos and are ready for being transformed again in new brass bricks or bars in full respect of the environment according to the #green philosophy of the company.